Business Activities

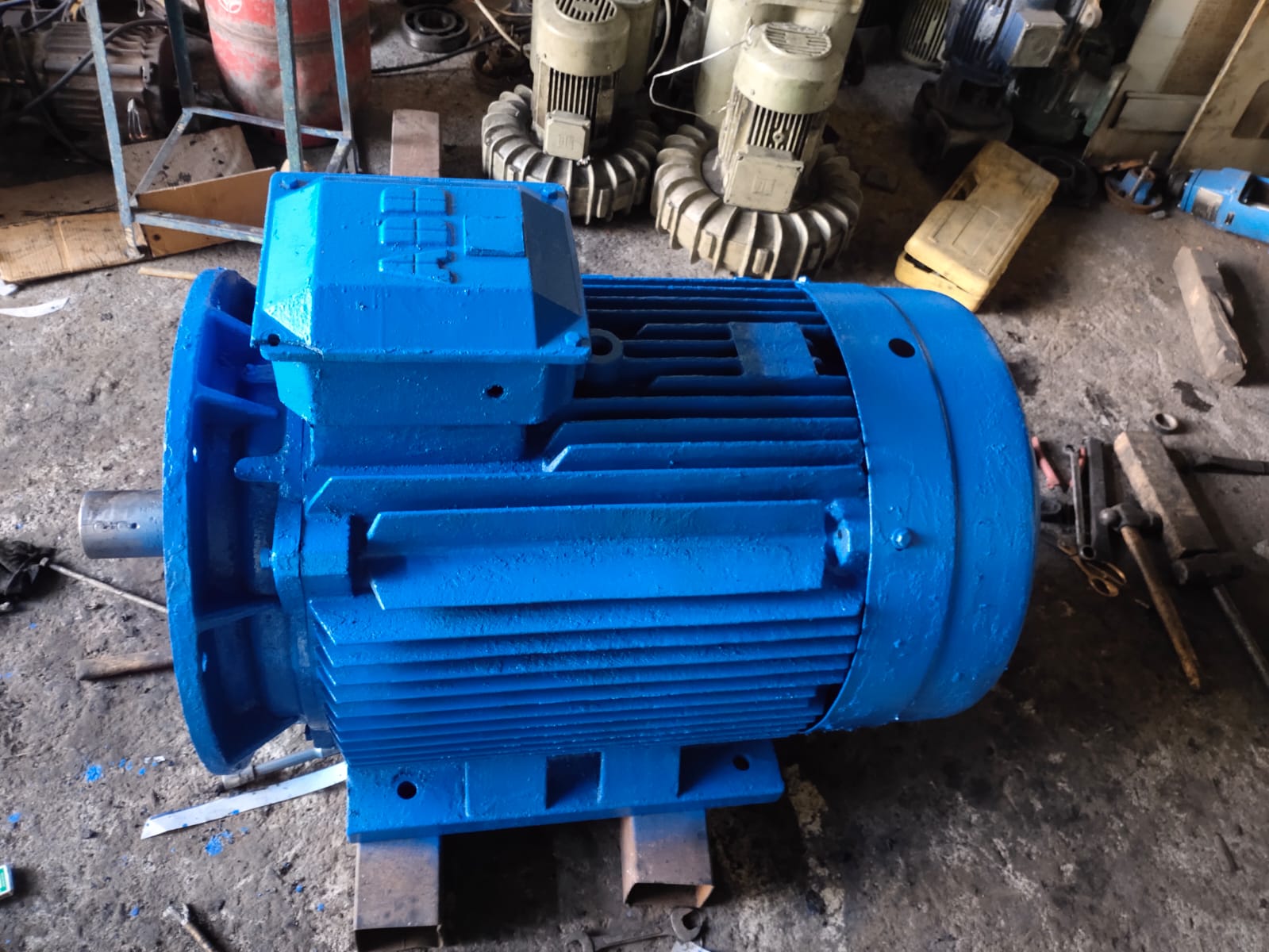

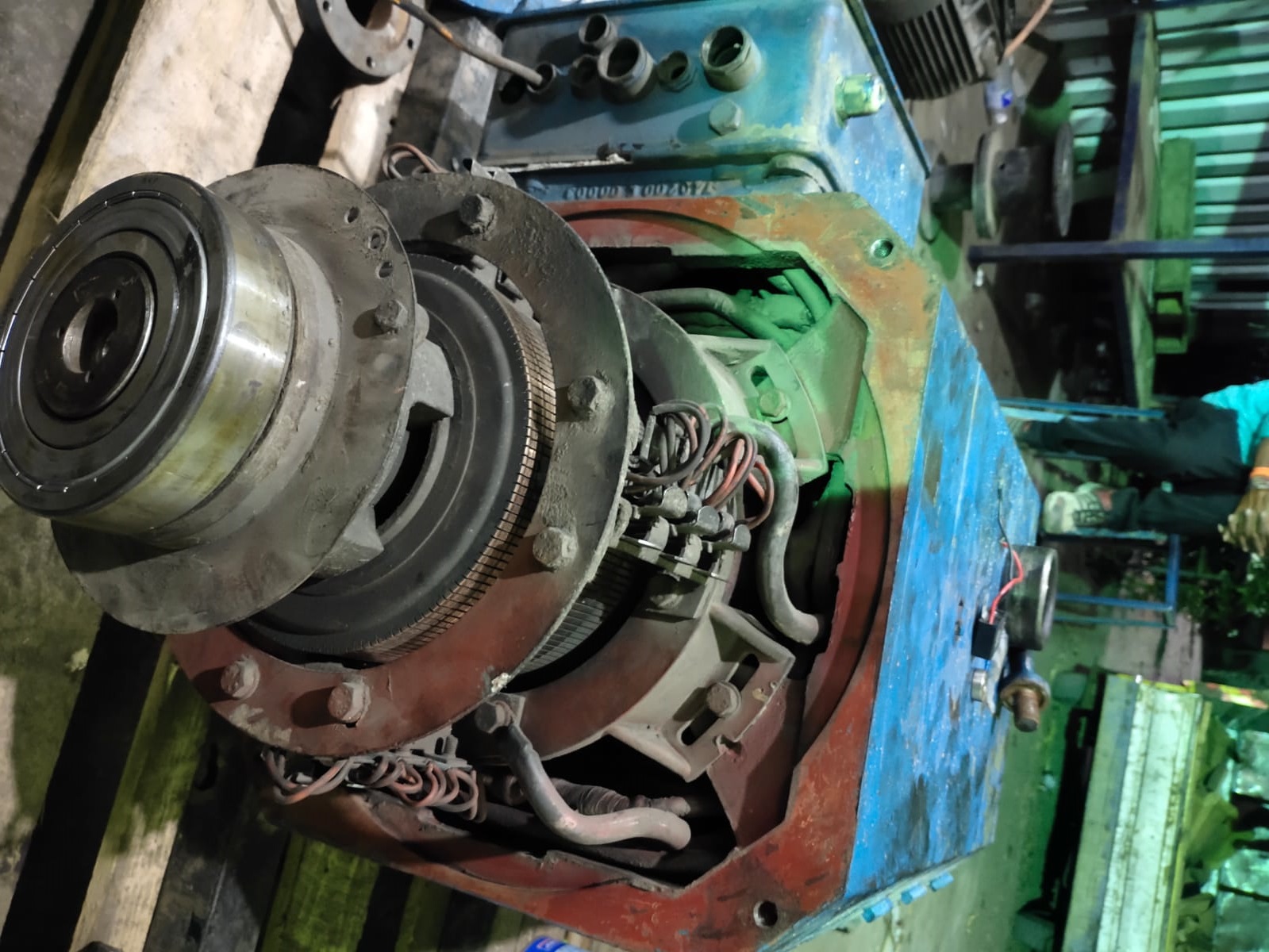

- Repairing / rewinding / servicing of medium & large capacity A.C. Motors (L.T / H.T)

- Rewinding and repairs of all types of DC Motors and Servo Motors

- Rewinding and repairs of alternators / Generators Medium & Large Capacity

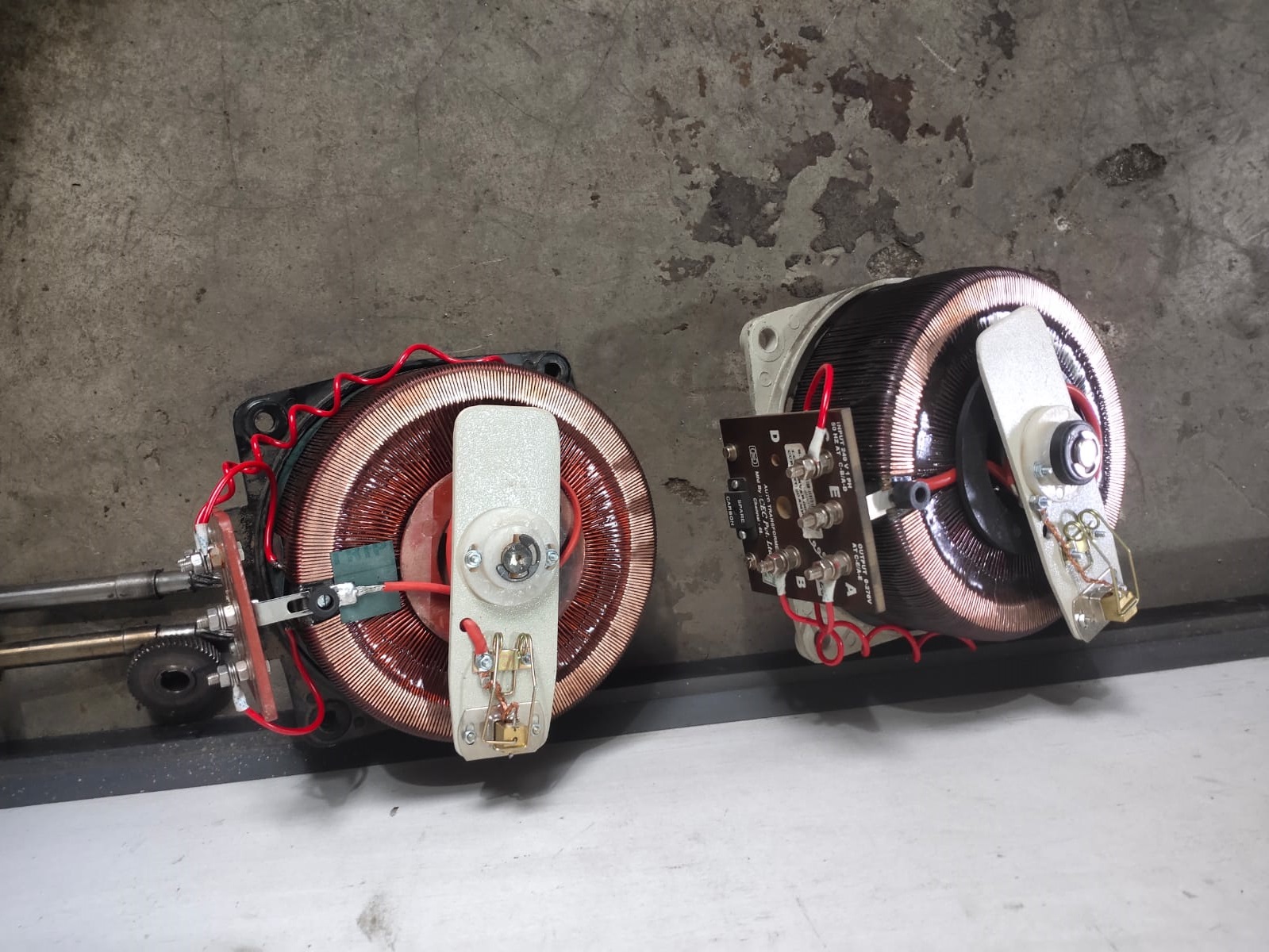

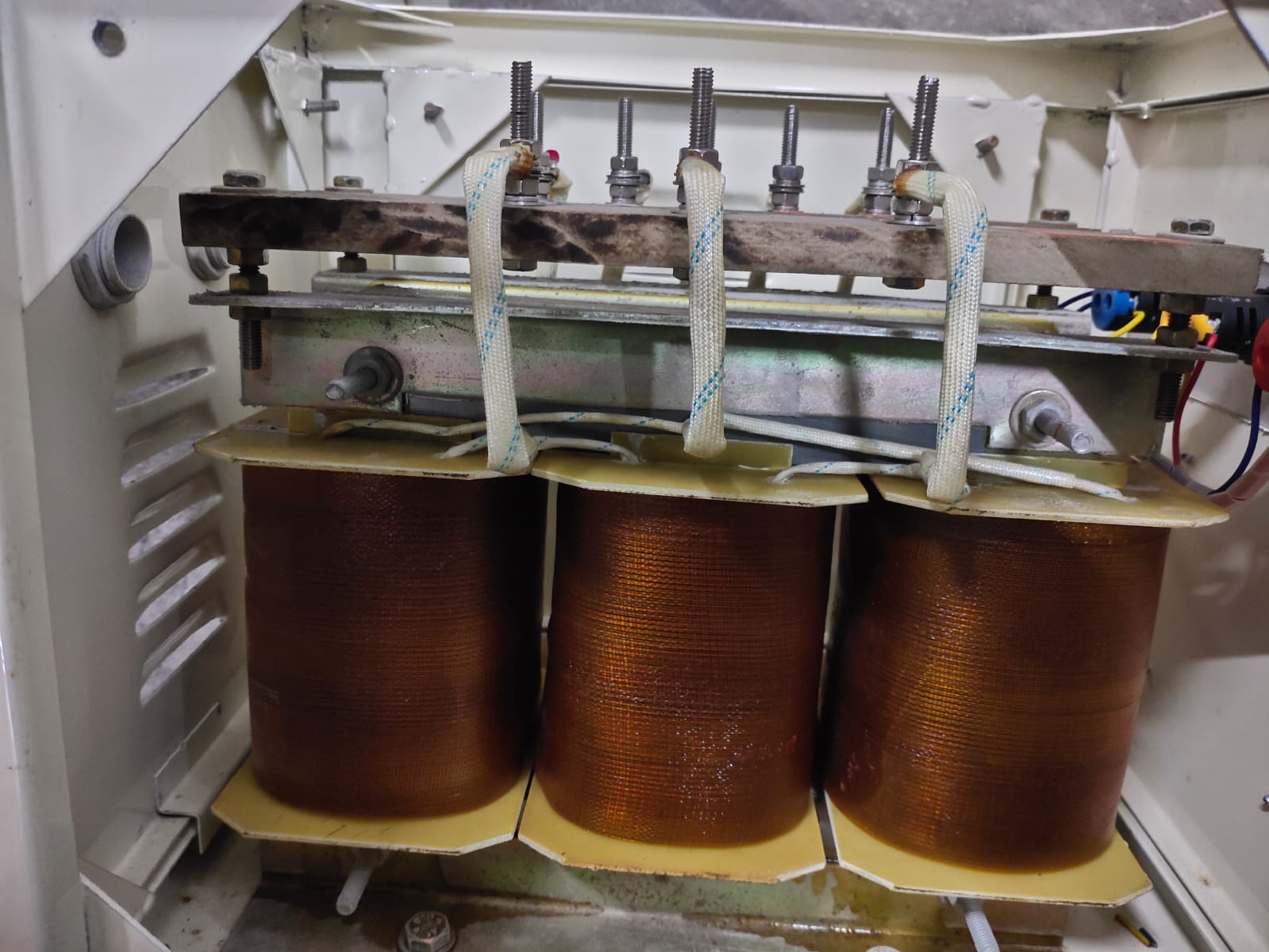

- Repairing and rewinding of transformers

- Rewinding of Medium and Large type Magnetic coils

- Rewinding of all types of motor pump sets

Infrastructure

Ashtavinayak Winding Works has a well equipped and well maintained workshop and engineering station.

We have a 2000 Sq. Ft. workshop and administrative office in Chakan MIDC.

Our Workshop Machinery includes :

- Lathe machine for machining works, heavy duty

- Lathe machine for light work

- Vertical Hydraulic press machine 200 tons capacity

- Radial Drilling Machine

- Coil winding machines & Coil looping Machines

- Temperature controlled electric oven for heating motors

- Induction Bearing Heater

- Oil Bath Bearing Heater

- Gas cutting and brazing setup

- Crimping tool for cables up to size 400 sq. mm

- Mechanical jack 50 tons

- Hydraulic puller setting 20 tons

- Mechanical puller 10 sets ( Different sizes )

- Bench Grinders

- Hand Grinders

- Air cleaner blowers

- Air compressors

Material Handling

- 3 Tons overhead hand operated crane

- 3 Tons Goliath Crane facility

- Manual stacker 2 TON

Quality Assurance:

We have state of art Q.A Testing and inspection facility comparable to the best in industry. Our Q.A is equipped with Testing Facilities :

- 1 KV Meggers ( Analog / Digital )

- Growlers for Armature & Rotor testing

- Multi meters ( Analog / Digital )

- Clamp meters upto 2500 Ampere

- Micro Ohm meters

- Vibration meter

- Tachometer for speed checking up to 10000 RPM ( Digital / Analog )

- High Voltage Break down tester 0 to 5 KV for motor testing

- 3 Phase supply facility for the testing purpose

- 3 Phase 200 Ampere & Dimerset

- DC Supply 440V, 100 Ampere, 200 Ampere & capacity for DC motor testing and other DC equipments